Last issue we talked about the steps leading up to establishing the Initial Application Area (IAA). We decided if the IAA was a manufacturing area, then the first thing to do would be to organize the products by value streams. Value streams have traditionally been thought of as product families. However, traditional families frequently were organized by customer or by type of product. This is not the case when organizing for a Lean deployment.

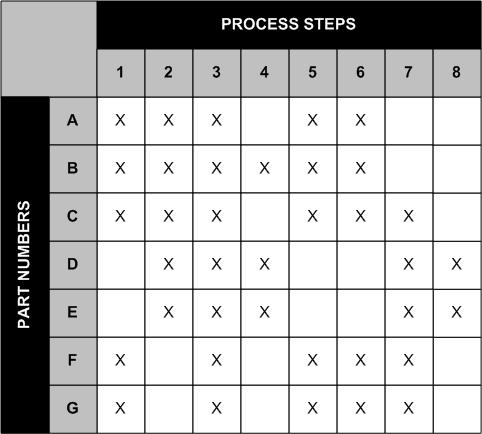

A value stream must be thought of as a product or group of products that share a common routing. That is to say they go through the same process in the same order across the same equipment. Determining your value streams is a fairly simple exercise. Create a matrix with the part numbers on the y-axis and all the manufacturing process steps on the x-axis. We must assume that every part number will not go through every process step. For example, some might get plated and others perhaps painted. Some might get heat-treated and some not, etc.

The example below will show you what I'm getting at.

This matrix is similar to the one found in the book

"Learning to See". In this light, which part numbers organize into a particular value stream? F&G certainly are, perhaps A, B&C could be, with some differences. How about D&E? Are you starting to grasp the idea of value streams?

The key element in organizing by value streams is a common routing and common equipment. That's it; size and customer aren't part of the equation.

Now let's introduce some common sense. There may be some over-riding argument that causes one to group by size or customer, but generally this is not the case. When planning for a lean deployment, it is important to go by value streams. When above mentioned advice is followed, then commonality is a must. Another exception might be for plants that have single part numbers and or processes. Also, short run job shops must be approached in a different light. However, this is all directed towards picking a product family for the IAA.

Once the IAA has been identified, it is appropriate to proceed in that area. Next month we will begin looking at the steps to make the IAA Lean.